PRODUCTS & SERVICES

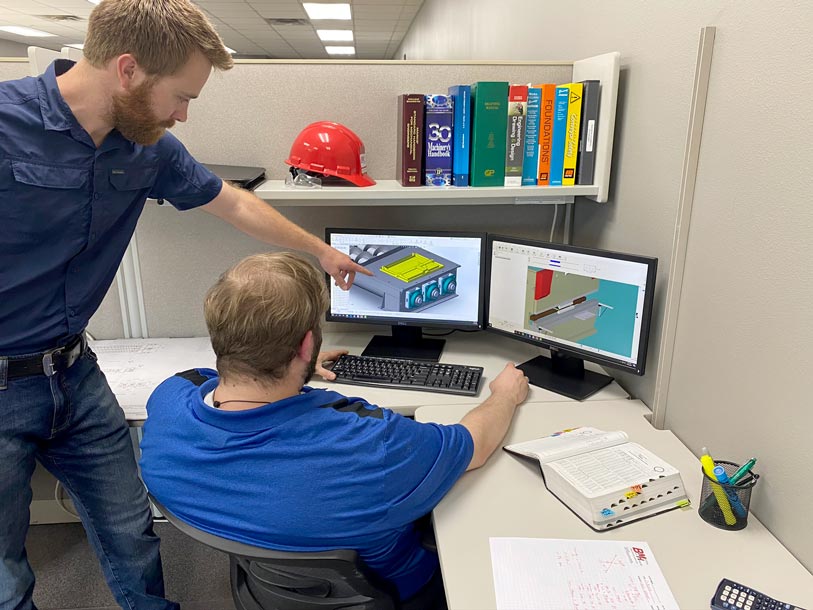

ENGINEERING & DESIGN

CDM Synergies’ design team thrives on challenging projects that other companies may have said “no” to. We spend the time to understand your goals and vision and convert them into 3D models and working drawings. Whether you are trying to economize an existing product, improve quality, or have an idea that needs to be developed, our experienced staff stands ready to assist you with your project.

Products

- Welding processes

- 3D modeling

- Design for manufacturing

- Value engineering

- Reverse engineering

- Radan sheet metal modeling program

- CAD/CAM programming

CUSTOM FABRICATION

CDM Synergies has evolved from being a small “mom and pop shop” to working with some of the world’s largest OEM’s and end users. While continuing to grow with and within our customers, we have held on to the core values and small business mentality the company was founded on, providing quality products for a fair price. Our capabilities range from building a one-off prototype drawn on a napkin to fabricating large volume, high tolerance, production run parts. We have a versatile staff that is able to adapt to meet our client’s needs. We take great pride in building long-term relationships with our customers and being a strategic partner on their projects. Our extensive experience with a wide range of projects, allows us to constantly assess and value engineer the project while sharing the economies with our customers.

Products

- Prototypes

- Production runs

- Conveyor frames and casings

- Augers

- Truck beds

- Water tanks

- Structural steel

- Catwalks

- Handrails

- Stairways

- Forming

DOT BRIDGE PARTS

CDM Synergies is a certified manufacturer for many minor bridge components and offers expedited services to our clients. We work closely with our customers and project stake holders to provide high quality, cost effective parts. Our management team shepherds your project through all phases. From creating the submittal packages to the application of high-grade finishes on the parts, we are with you the entire way. Our QC inspectors create a thorough and organized documentation package for the governing bodies that reduce “approval to ship” durations once the product is complete. We want to be your source for fabricated bridge component on DOT projects in the upper Midwest.

Products

- Expansion joints

- Bearings

- Diaphragms

- Ornamental railing

- Structural railing

- Miscellaneous parts

(Certified with MNDOT, WISDOT, NDDOT, SDDOT, IADOT, MODOT & KSDOT)

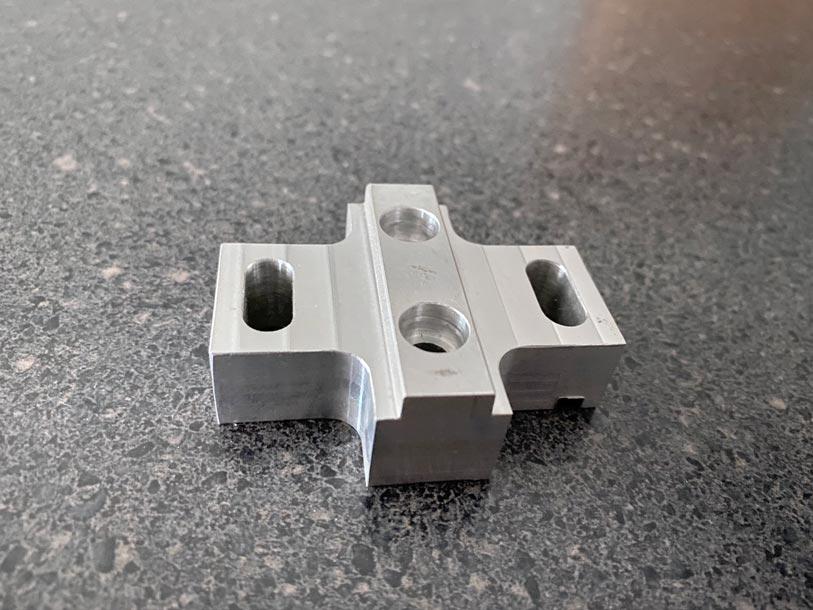

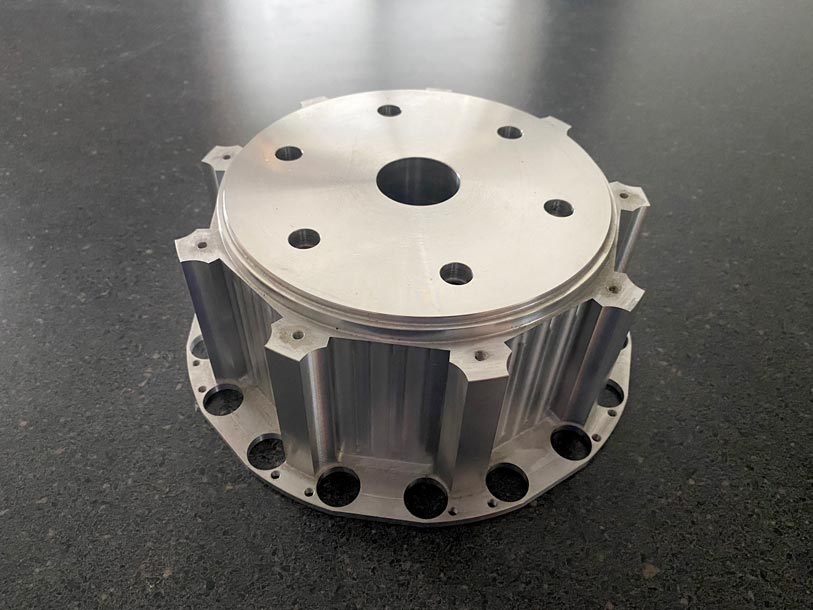

CNC & MANUAL MACHINING

CDM Synergies has a variety of manual and CNC machining equipment along with a team of skilled machinists. The “think outside the box” philosophy our team embraces, positions us to provide unique solutions and solve manufacturing challenges. Whether your needs are production run machining or large fabrications with pre weld and post weld machining processes, we can provide a cost effective approach with reduced lead times. We are your source when you need quality work done right.

Products

- Vertical milling

- Horizontal milling

- Turning

- Part inspection

COATINGS

In our continuing effort to improve on our quality and scheduling outcomes, CDM Synergies invested in our in-house painting capabilities. Today we offer a diverse line of specialty performance coatings not only for in-house projects, but to the general industry as well. Our product line includes coatings with various properties such as; chemical resistance, sound attenuation, thermal insulation, chemical resistance, and UV resistance. Our large-scale blast and paint booths give us the flexibility to process parts both large and small. It is not uncommon for us to run multiple projects with different coating systems through our facility in a single day. Whether you have a specific coating in mind, or are looking for help specifying a coating system to meet your needs, our experienced staff is happy to assist you.

Products

- Steel grit media blasting

- Glass bead blasting

- Liquid paints

- Specialty coatings

- Hot dip galvanizing

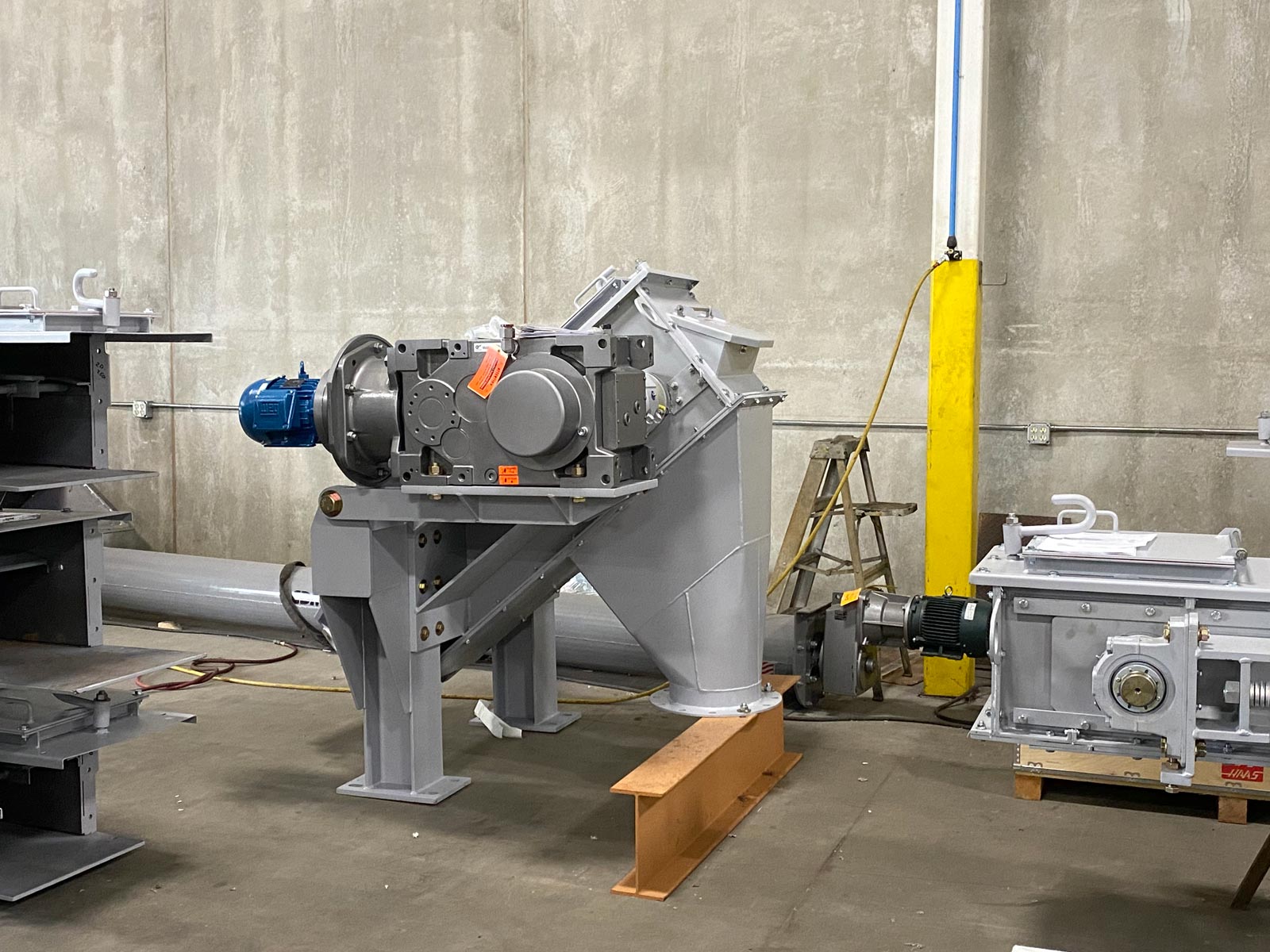

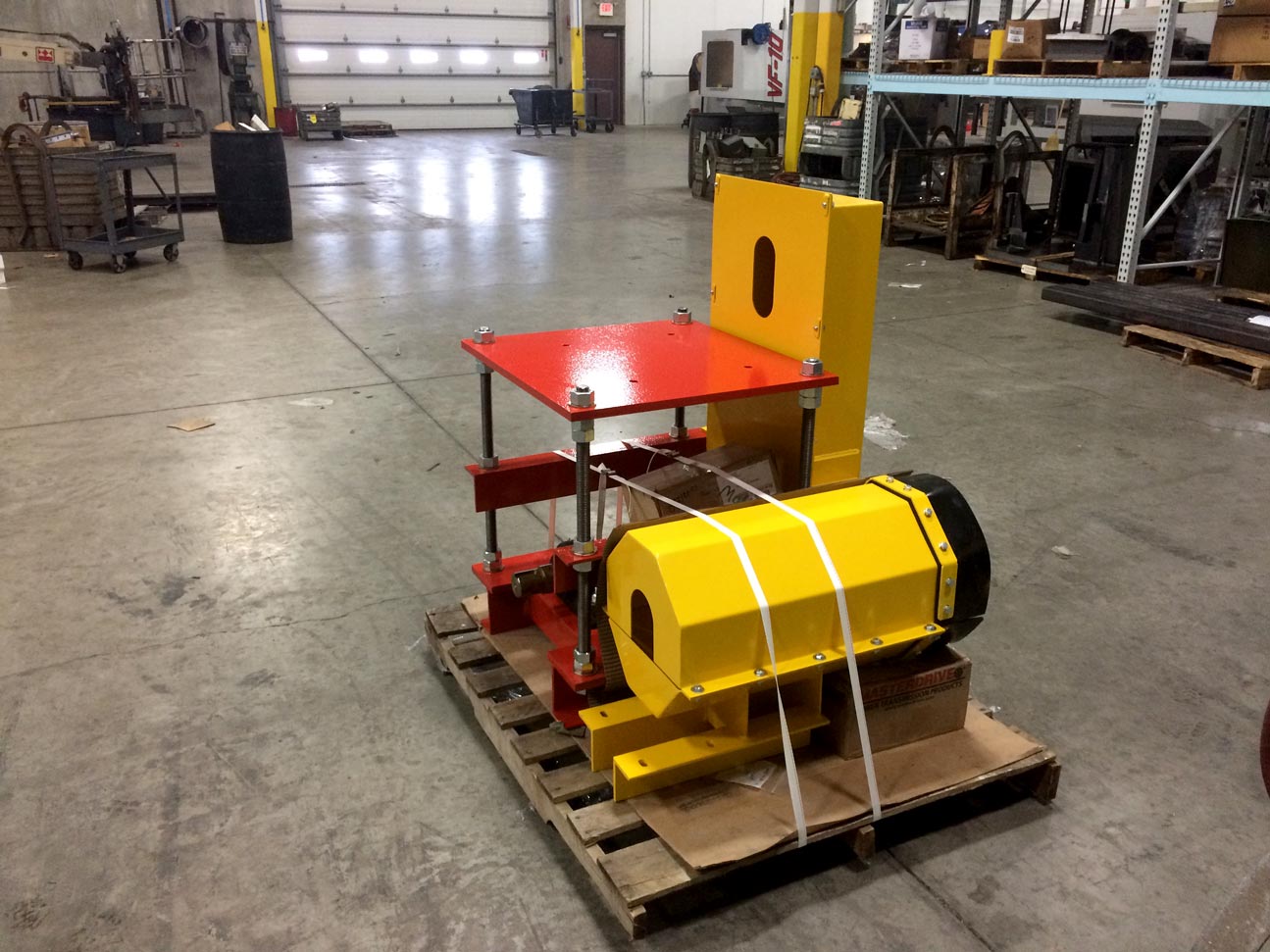

ASSEMBLY

A project is not complete until it is assembled and ready for delivery to the end user. CDM Synergies has a dedicated team of experienced craftsmen that assemble a professionally built finished product. We are able to receive, store and stage your procured components, bringing them together with our manufactured parts in one seamless effort. Our team is well versed in mechanical, electrical, hydraulic, and pneumatic systems. We do full scale factory acceptance testing for our clients. This service helps mitigate the risks associated with building custom, one-off pieces of equipment. If issues arise, we work directly with you to provide a viable solution in a timely manner. We are ready to be your partner on your next project.

Products

- Final equipment assembly

- Shop wiring

- Test running

EQUIPMENT REBUILDS

Since inception, CDM Synergies has been involved in equipment rebuilds and modifications. Our flexible staff and small business mindset allow us to react quickly to keep you working. We welcome any job, from planned outages to unexpected breakdowns and certainly understand emergency situations where you need to be up and running as soon as possible. This could be as small as replacing spray bars on a wash plant to completely re-flighting an asphalt drum. We pride ourselves as problem solvers, being able to reverse engineer and manufacture on the fly when time is of the essence. Having the resources to fabricate, machine, blast, paint, and assemble all under our roof helps us be cost effective and keep lead times short. We strive to provide solutions that exceed our customers’ expectations.

Products

- Crusher liners

- Wash plants

- Dryer and asphalt drums

- Vibratory equipment

- Shaft repairs

- Hub rebuilds

- Replacement components

New Equipment

The CDM Synergies name has long been associated with high quality, durable equipment. Our teams exacting standards sustain every project from conceptual design, through the manufacturing process and onto your jobsite. We have implemented a strategic organizational structure which allows the design team to maintain oversight of every project from inception through commissioning. This guarantees our clients receive exactly what they want and need. We understand the complexities associated with custom equipment and welcome our client’s input and vision throughout this dynamic process. Please reach out to our team with your next project.

Products

- Wash plants

- Feed bins

- Asphalt plant equipment

- Conveyors

- Portable stackers

- Replacement drums

- Slipform rail molds

- Vibratory feeders

- Vibratory screens

- Drag slats

- Screw conveyors

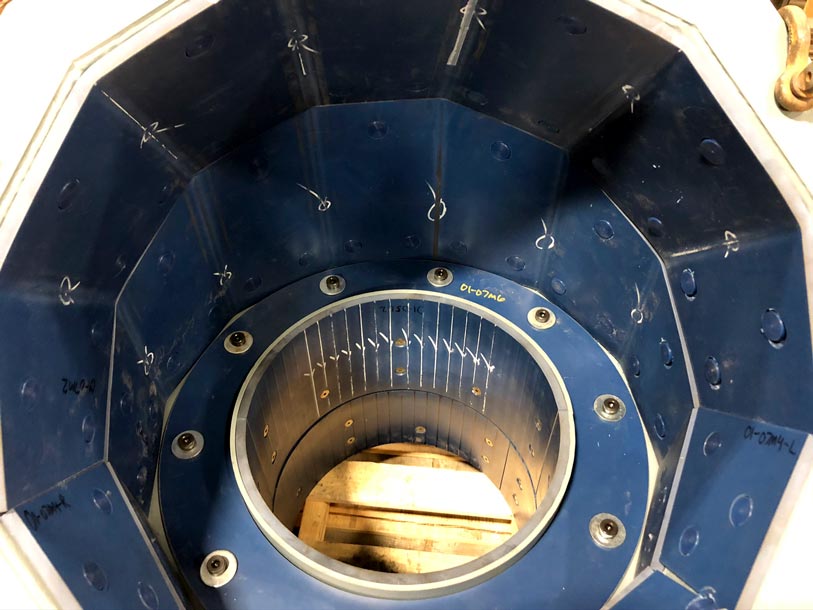

WEAR PLATES & LINERS

Whether you need reverse engineered replacement wear liners for existing equipment or a completely new design, CDM Synergies is your source. We offer a wide range of products that are available for your specific application. We have experience using everything from typical abrasion resistant steel to exotic corrosion resistant alloys. Let our experienced team work with you to provide a true solution to your wear issues.

Products

- AR 400

- Hardox 450

- Chromium Carbide

- UHMWP

- Urethanes

- Spray on ceramic

- Bonded ceramic tiles

MAJOR EQUIPMENT LIST

CDM Synergies is constantly investing in state-of-the-art equipment and CNC machines staying at the forefront of technology. This allows us to constantly improve our efficiencies and quality on the products we manufacture and pass the benefits on to you. Our reliable fleet of equipment helps ensure tight timelines can be met.

Products

- 400 ton x 14’ long CNC press brake

- 60 ton x 6’ long CNC press brake

- ½” thick x 10’ long plate shear

- 10’ x 28’ CNC high definition plasma/oxy-acetylene plate cutting table (up to 2 ½” thick with the plasma and up to 6” thick with oxy-acetylene)

- (3) vertical band saws with cutting capacity up to 24”

- Multiple Ironworkers with capacities up to 125 tons

- Pulse welders up to 500 amps

- Vertical CNC mills with travels up to 10’

- Horizontal CNC mill with fourth axis

- Lathes with lengths up to 10’

- 800 amp sub-arc hard surfacing machines

- Overhead cranes with lifting capacities up to 20 tons in a single bay

- 24’ wide x 70’ long x 16’ tall blast booth with media recycling system

- 24’ wide x 70’ long x 16’ tall side draft paint booth

- Forklifts with lifting capacities up to 16,000 lbs

Contact our team of specialists to discuss your project

Our goal is to satisfy and respect your unique project needs, large or small. Contact us today to talk with a team member.